What Is Lean Six Sigma?

Six Sigma is a rigorous and disciplined process improvement methodology that uses data and statistical analysis to measure and improve any organization’s operational performance. Six Sigma methodology was developed by Motorola in 1986.

What Is Lean Six Sigma? An Organizational Perspective

By Priya D

Six Sigma is a rigorous and disciplined process improvement methodology that uses data and statistical analysis to measure and improve any organization’s operational performance. Six Sigma methodology was developed by Motorola in 1986. General Electric (GE), under the leadership of Jack Welch, embraced Six Sigma in 1995 and reported $12bn of savings in their first 5 years. After observing GE’s many successes with Six Sigma, other organizations adopted six sigma methodology for process improvement.

By using this management methodology, companies would be able to eliminate defects in any process. A process is said to have achieved six sigma if it produces 3.4 defects per million opportunities. For a process, defect is considered as anything that is outside the customer specifications.

Six Sigma Methodologies

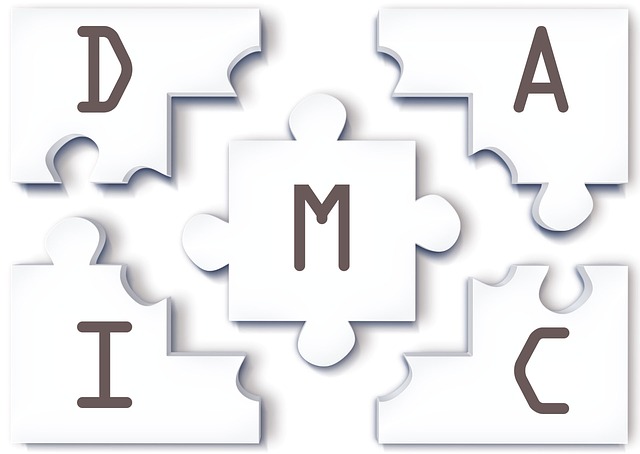

Mainly two methodologies used in Six Sigma are DMAIC and DMADV. DMAIC stands for Define, Measure, Analyse, Improve and Control and is used for existing processes. DMADV is used for new processes and it stands for Define, Measure, Analyse, Design and Verify. Each phase of DMAIC and DMADV has various deliverables to be achieved while executing a process improvement project. DMAIC methodology helps in reducing the variations in a process by identifying the root causes for any problem and resolving them by implementing the best solution. DMADV methodology helps to design a new process after analyzing the customer requirements.

[misi ad=”Management”]

Six Sigma in an Organisation

An organization usually makes a roadmap for Six Sigma implementation. The roadmap involves the creation of infrastructure, identification of six sigma projects, project group selection and six sigma training, project execution and six sigma implementation. Different people in an organization, when involved in six sigma implementation take up roles and responsibilities as Champions/Sponsors, Process Owners, Master Black Belt, Black Belt, Green Belt and Yellow Belt. Black belts, Green Belts, and Yellow Belts would form project teams and execute six sigma projects.

For the organization, Six Sigma would benefit by reducing Defects (50-90%), Waste (10-60%), Rework, Process cycle times (20-50%) and improvements in Quality, Production Efficiency, Productivity (10-20%), Customer Satisfaction, Capacity, Profitability and Competitive edge.

Six Sigma has proven to be a successful process improvement methodology in industries like Manufacturing, Telecommunications, Banking, Finance, Insurance, IT, ITES, BPO, KPO, Healthcare, Pharmaceuticals, Logistics, Shipping and Supply Chain.

Conclusion:

A company or organization can take best advantage from Six Sigma methodology by providing right training and skills to its employees. Employees who are equipped with Six Sigma expertise and knowledge can solve problems in the best way to enhance productivity and spontaneously this will lead an organisation towards growth and success.

Article Source: What Is Lean Six Sigma? An Organizational Perspective

[misi ad=”Adsense”]